Thread Types in Hydraulic Systems

Thread types of fasteners and components used in hydraulic systems vary according to system pressure and different regions around the world. Thread types are important in choosing the right component and determining some spare parts in hydraulic pumps, directional control valves and inline valves. While NPT threads are mostly used in America and Canada, BSPP threads are mostly used in Europe, Asia, Australia, New Zealand and South Africa. In this article, we will talk about how we can determine different types of threads and what are the general characteristics of them. This information will save us time during the installation and maintenance of hydraulic systems. First, let’s take a look at some general terms:

-

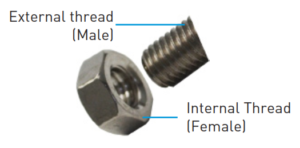

The thread on the outer and inner surfaces that are compatible with each other are expressed as male and female.

-

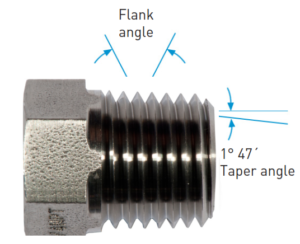

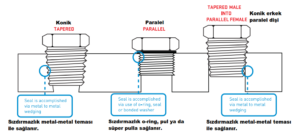

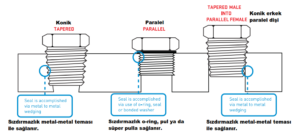

The design of the thread can be parallel or tapered.

-

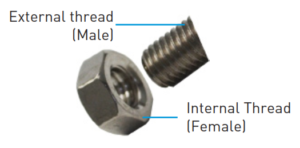

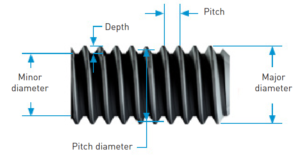

Major diameter is determined by thread tips. Thread pitch is defined as the path taken by the screw in one revolution. The pitch diameter is the distance of two opposite flanks or the distance of the centreline of the profile. The thread root diameter is the diameter measured from the thread bottom of the screw.

-

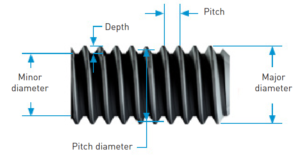

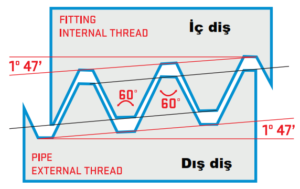

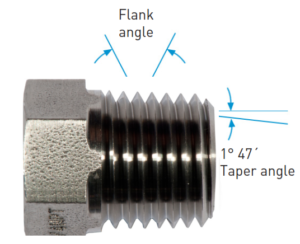

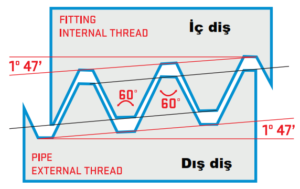

In tapered threads, the angle between the taper and the screw axis is expressed by the taper angle.

Some of the thread types commonly used in hydraulic systems are as following:

-

Metric (Coarse and fine thread)

-

NPT/NPTF

-

BSPP (BSP, parallel)

-

BSPT (BSP, tapered)

-

UNC/UNF threads

Metric threads

-

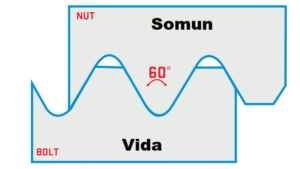

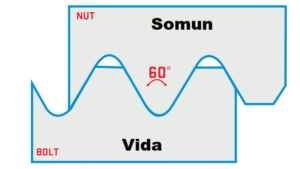

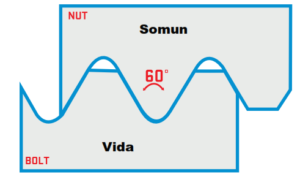

ISO metric thread type is one of the first thread types accepted in international standards. The flank angle is 60° and thread is parallel. It can be coarse or fine thread. The difference is that the pitch is smaller in the fine thread. Especially in Germany, metric parallel threads are used.

NPT threads

-

This thread type is the most commonly used type in America and Canada. It is also called American pipe thread. The flank angle is 60° and threads are tapered. There are two types, NPT and NPTF.

Whitworth threads (BSPP/BSPT)

-

This thread type is available in two types as BSPP (G) parallel and BSPT (R) tapered. BSPT tapered threads are more commonly used in China and Japan, while BSPP threads are common in the UK, Europe, Asia, Australia, New Zealand and South Africa. The flank angle is 55°. Tapered threads are sealed with Loctite, while parallel threads usually use bonded washer.

UNC/UNF threads

-

This thread type appears as UNF (fine thread) and UNC (coarse thread). UNC thread is compatible with ISO Metric thread. The flank angle is 60° and the threads are parallel. This thread type is divided into three groups as 1A/2A/3A according to assembly requirements. Among them, 2A/2B is the commonly used group.

To identify different types of threads, we can follow the steps below:

-

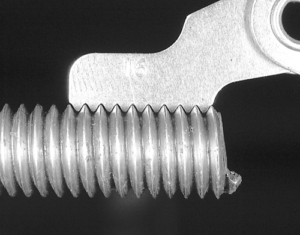

First of all, it is determined whether the thread is male or female. If the threads are are outside, they are male, if they are inside, then it is female.

-

Then we can check whether the thread structure is parallel or tapered. If it can not be determined by eye, the beginning and the end of the thread can be measured with a caliper. If the result is the same, the thread is parallel. In addition, sealing elements can also give us information. While metal-to-metal contact provides sealing in tapered threads, components such as o-rings and washers are used in parallel threads.

-

Measure the outer diameter of the thread. There may be differences between the value we measure and the value in thread table due to production tolerances.

4. The pitch is determined using the pitch gauge. Then, the information in all steps is evaluated and a selection is made from the thread table.

Sealing elements also vary depending on thread design. O-ring or super washer can be used when the female and male threads are parallel. O-rings are generally preferred due to ease of installation and cost. Loctite or Teflon tape can be used on tapered threads.

Pictures are used for training purposes.

Sources

-

Motion and Control Technology Blogs, Parker, Turkey

-

Teesing, Types of Thread